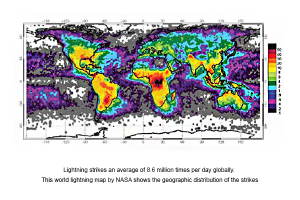

A lightning strike can put a vehicle scale out of service in an instant. Lightning damage can be very costly, requiring the replacement of unprotected electronic equipment. Even if a warranty covers repair costs, you still face the cost of the business you lose every day that your scale is not operating.

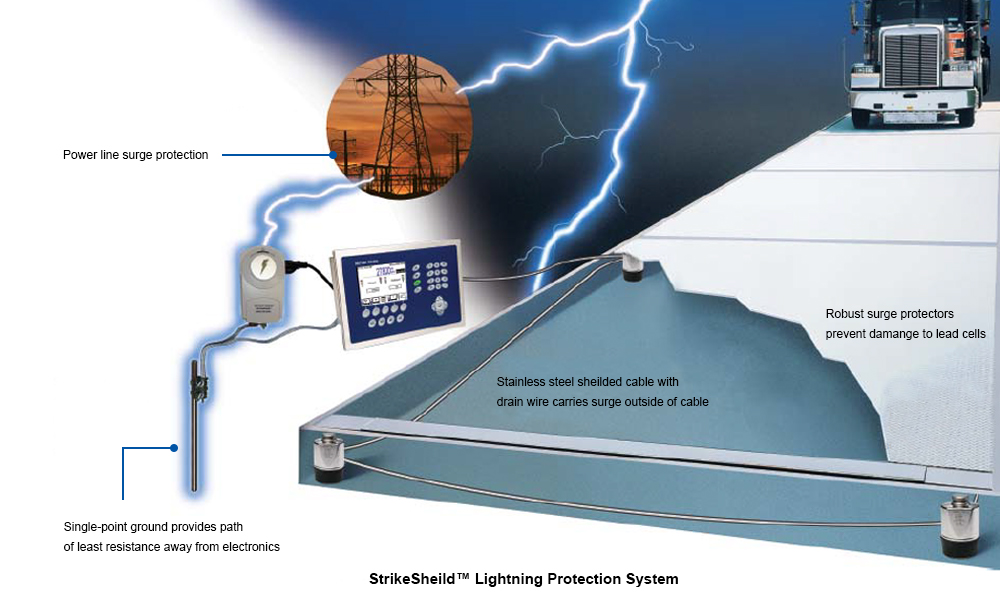

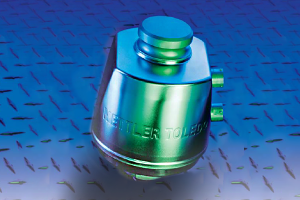

METTLER TOLEDO provides complete protection against lightning damage.

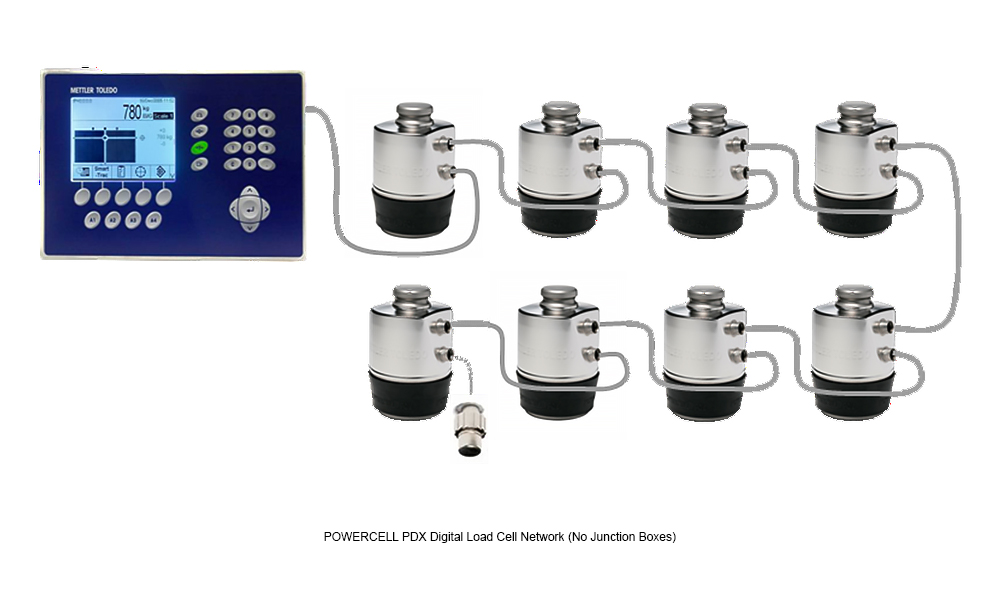

The StrikeShield™ protection system is designed to be the main line of defense for your entire vehicle scale system: load cells, cables, and terminals. The average lightning strike is approximately 30,000 amperes. The POWERCELL® PDX® load cell system has been proven in independent testing to survive multiple lightning strikes up to 80,000 amperes. That’s more than twice the destructive power of the average lightning strike. No other scale manufacturer has had its system as thoroughly tested by independent laboratories.