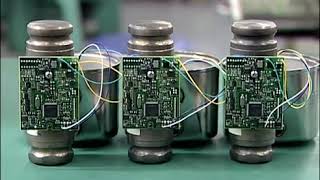

Load cells are the heart of any truck scale. They are the sensors that measures the weight of objects on the scale deck. Most truck scales require 6-12 load cells. They must work together flawlessly to provide accurate weight readings.

Analog Load Cell

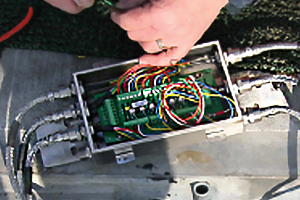

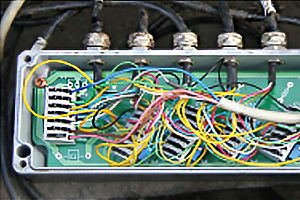

A precision-shaped piece of metal, often steel or stainless steel, that changes its shape slightly as a force (weight) is applied. The change is monitored by electrical strain gauges. The result is an analog voltage signal that varies from the input signal based on the load. The analog signals from all of the cells are summed in one or more junction boxes at the scale. The combined signal is then transmitted to the scale house, where it is measured and converted to a digital signal that indicates the weight.

| Pros | Cons |

|---|---|

| Low Cost | Limited accuracy |

| Well-known technology – most scale companies offer an analog load cell option | Typical load cell life is 3 – 5 years |

| Requires junction boxes which are a common source of problems | |

| Require time-consuming manual adjustment for calibrations | |

| Cannot check the status of individual load cell signals in the system |